PASTEURIZING SYSTEM

AUTOMATED HEATING, STORAGE AND TRANSFER OF BIOPULP

Modular and scalable to any sized application, the pasteurizing system is fully-automated and integrated into the heating system for the anaerobic digester. This unique efficiency significantly reduces operating costs.

Click the arrows to the right and left of the image to view the gallery.

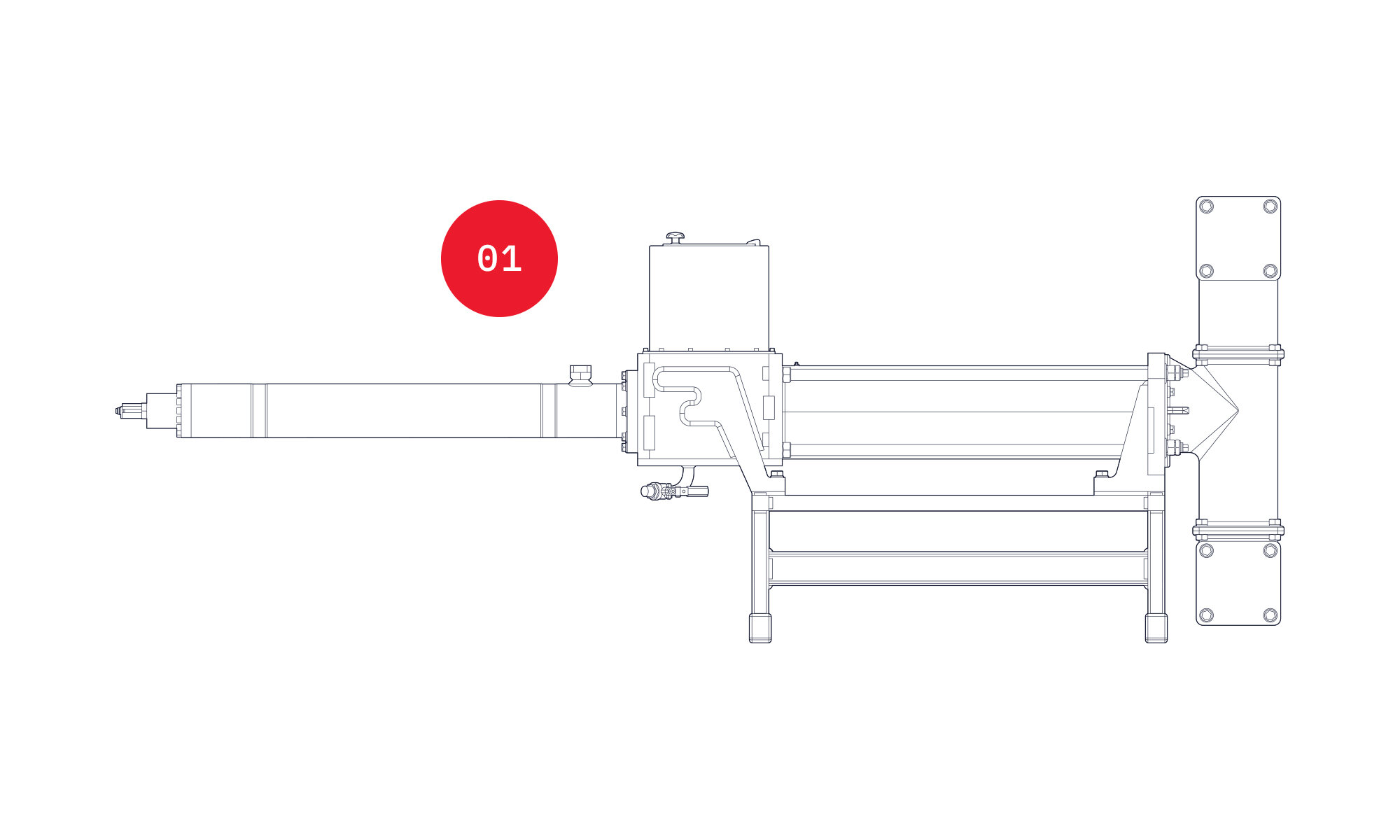

01 Pumps

02 Heat Exchangers

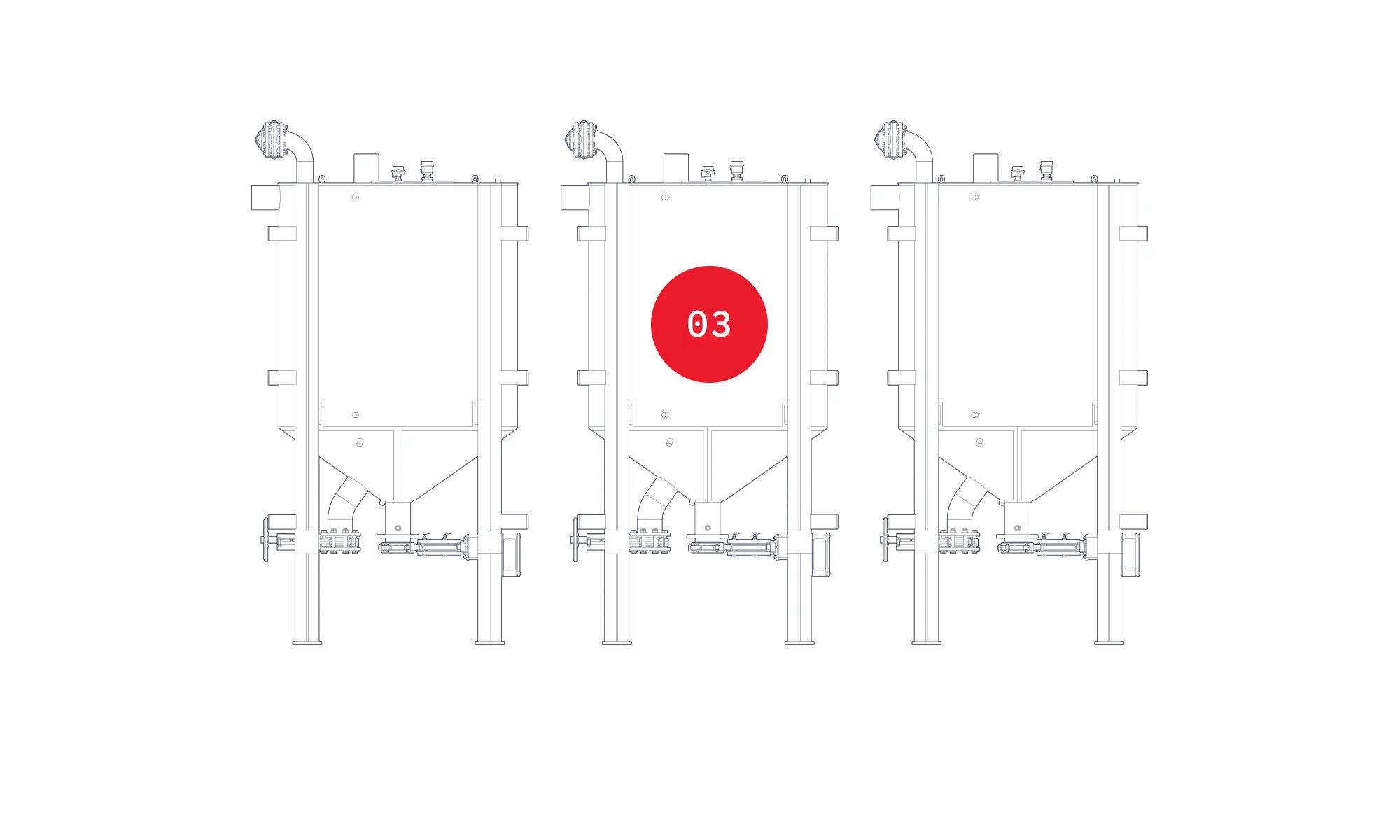

03 Holding Tanks» Designed to handle highly abrasive materials with high solids contents at high temperatures

» Biopulp is heated to a minimum of 70ºC and held for 1 hour to meet regulations before being sent to the digester

TECHNICAL SPECIFICATIONS» No mechanical movement in the system means no fouling of equipment and low maintenance costs» Each pasteurization component is modeled and sized based on a per project basis» Back-cooling loop regulates the temperature of the Biopulp before entering the digester tank to ensure optimal digestion25% Total Solids

Read our blog post to learn more about

Double-Tube Heat Exchangers and their Role in Biogas Production

No Dilution Required

Energy-efficient

High Heat Transfer Rate Completely Eliminates the Need for In-Vessel Heating