THE HIGH SOLIDS APPROACH - THE SCIENCE & ENGINEERING BEHIND AD SUCCESS

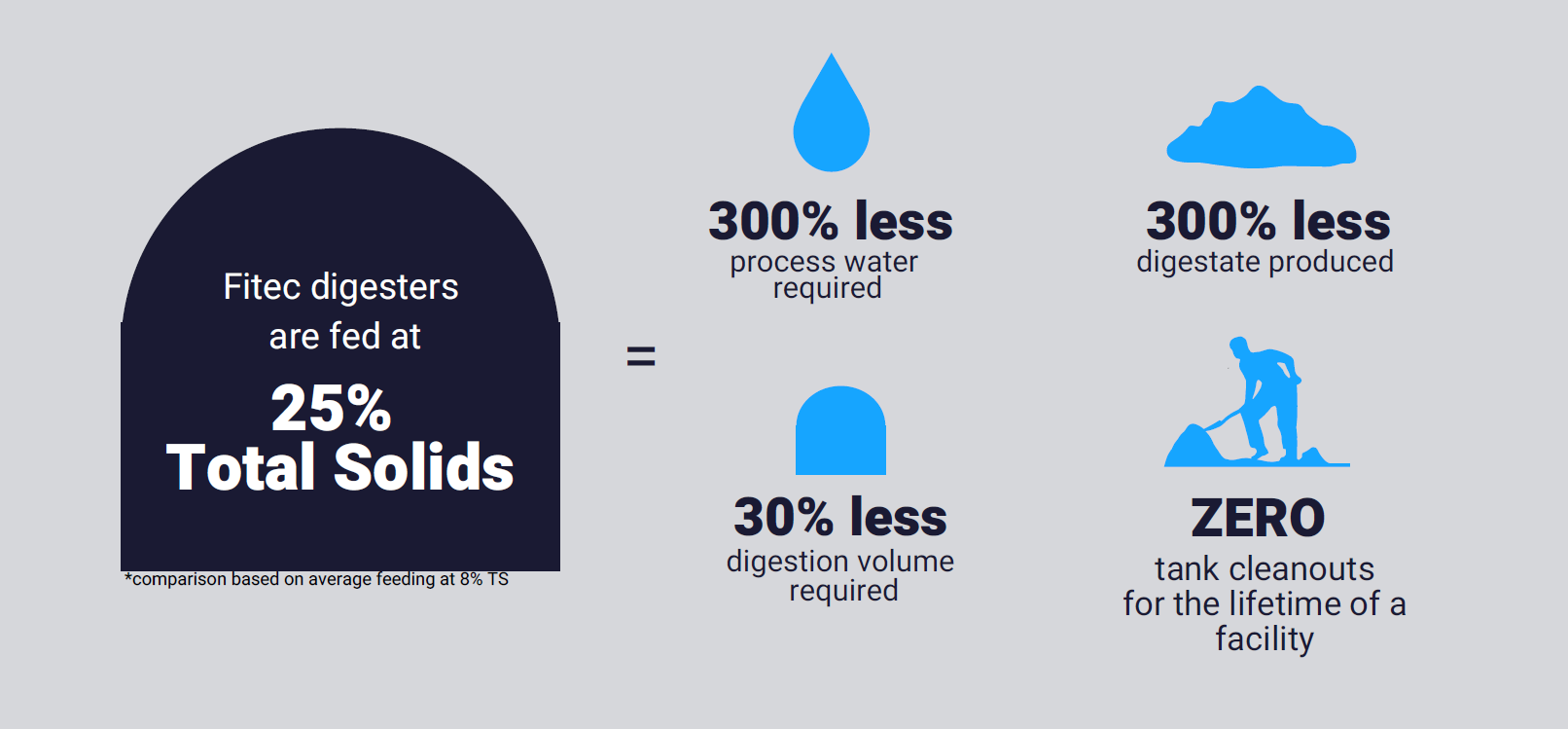

The technology and equipment that Fitec designs for their facilities are purpose-made for the tough conditions in anaerobic digestion (AD) systems. By using feedstock at High Total Solids (TS) levels, all aspects of a system can be made more efficient:

Less water

Fewer pumps

Less electricity and heat consumption

Less trucking costs

These principles are applied to all types of digesters: agricultural, food waste, and mixed waste. Fitec has a high level of expertise in all these areas. Additionally, we offer a Self-Cleaning Digester option that eliminates the need for cleanouts. Read on to learn about all the CAPEX and OPEX advantages of the High Solids Approach.

DO NOT ADD WATER!

In most AD process flows, considerable amounts of water are added ahead of the digestion stage in an effort to support the removal of non-digestible contaminants. Whether for packaged food waste or high sand and grit agricultural wastes, water is used to accentuate density differences in the materials. But water does not contain energy like feedstock does. And aside from not contributing to the bottom line, it also increases operational costs both to bring it in to site and to move it through the system. This cost takes the form of electrical demand and wear on equipment due to increased throughput.

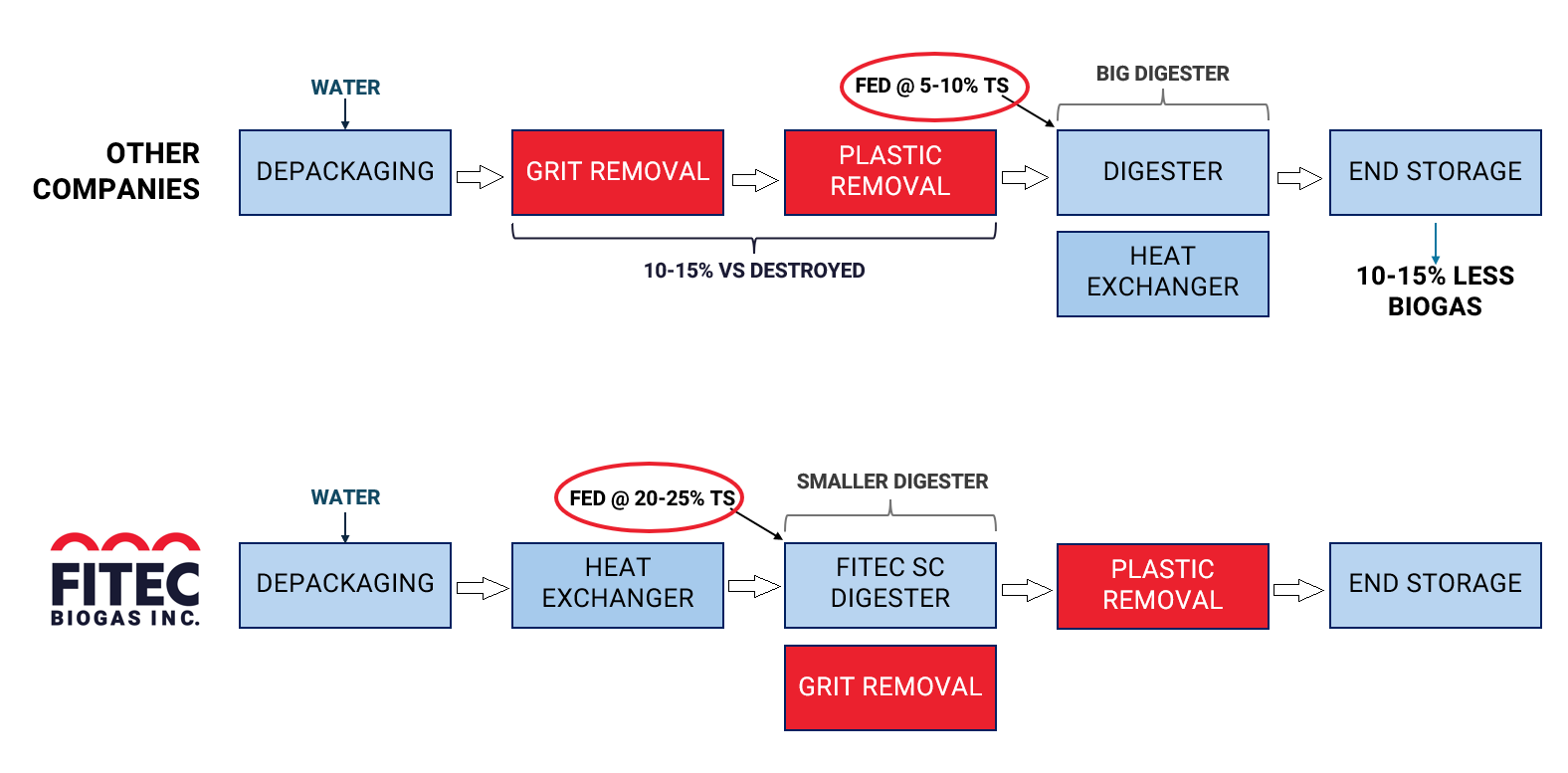

IN-DEPTH PROCESS FLOW COMPARISON

Let’s compare two different scenarios.

Comparison of a typical AD Process Flow and the Fitec System Process Flow

In the first instance, contaminants are removed before digestion using water to dilute the feedstock. As a result, volatile solids (gas-producing solids) are lost, translating to an equal reduction in biogas production at the end of the process. Next, the digesters are fed at a total solids of approximately 5-10% which works well for conventional pumps, but to accommodate the added non-energy producing volume, digester tanks must be very large. The other considered ‘advantage’ of the large tank size is to delay the inevitable cleanout that will be required as the remaining non-digestible contaminants settle inside the tank. The result is an increased CAPEX, and a reduced production of biogas.

In a Fitec system, feedstock undergoes minimal pre-treatment and the digesters are fed at a total solids of 20-25%. The equipment inside the Fitec Self-Cleaning Digester tank removes these contaminants on an ongoing basis, keeping the entire tank volume available for energy-producing feedstock. Volatile solids are retained in the system and contribute to biogas production. Tank sizes can remain smaller and smaller and fewer pumps are required.

The Fitec Self-Cleaning Digester

Let’s take a closer look at how the Fitec system operates. Once the feedstock begins to decompose, there is a natural separation effect within the tank and the light fraction of contaminants such as plastics or straw will float to the surface, while the heavy fraction such as grit and sand, will sink to the bottom. Our Self-Cleaning Digester technology takes advantage of this naturally occurring phenomenon and deals with this problem inside the tank. A skimming system with a screw press is used to remove the light fraction from the surface and a floor sweeper system and settling tank to remove the heavy fraction from the floor. Our low wear pumps are designed to handle thick slurries which allows the system to run with up to 77% less water. As a result, tank cleanouts are never required .

The end result of operating at a higher TS means

A lower OPEX :

More energy being produced per ton of feedstockLower water requirementsLower energy useLower disposal costsLower throughput and therefore slower wear on equipmentCompletely eliminate tank cleanouts.

And a lower CAPEX:

smaller tank sizesfewer pumps and smaller pumping requirements.

Though the components of this system work optimally when used together, each has its own individual benefits and can be deployed in any project. Fitec pumps and heat exchangers can handle the tough conditions of anaerobic digestion and improve the efficiency of any biogas project. For facilities with access to clean feedstock, the Fitec system can be built without the tank cleaning equipment and still showcase its high profit producing characteristics. Even existing facilities can be retrofitted with individual subsystems to improve less-than-optimal performance.

Contact us today to learn how The Fitec High Solids Approach can make your biogas project more profitable and successful.