ELIMINATE TANK CLEANOUTS WITH FITEC

Anyone who has been involved in the operation of anaerobic digesters understands the pain of tank cleanouts. Aside from the actual cost of cleaning, there is also the lost revenue from downtime while the tank is being emptied and while the biological system ramps up again to produce gas at optimal capacity. But at Fitec, we’re here to tell you: There’s a better way.

Non-digestible Contaminants

All feedstocks used in anaerobic digestion systems contain some portion of non-digestible contaminants. These contaminants do not contribute to the production of biogas and can cause many downstream problems, mechanical and otherwise. “Clean” feedstocks do exist and usually come from food processing facilities, but these can be difficult to source and usually still contain a small portion of non-digestible contaminants. While most people associate contamination with food packaging, even pre-consumer wastes can contain a high volume of contamination (think sand and gravel in manure).

Non-digestible contaminants can be separated into two broad categories: floating and sinking. For the purpose of this post, we will be focusing on sinking contaminants, or the heavy fraction. These contaminants are made up of materials that fall out of suspension in the digestion vessel. They include things like sand, grit, bone, metal wastes like screws or nails, etc. Highly contaminated feedstocks are often pre-treated to remove problem materials before they enter the tank, but this comes with its own set of challenges, and are addressed in our blog post on high solids AD. Still, even the most advanced pre-processing methods cannot capture all the contaminants without losing a large amount of the digestible or energy-containing material. Regardless, any contaminants that remain in the feedstock that make their way into the digester tank will begin to settle at the bottom of the tank.

Sedimentation

The accumulation of non-digestible contaminants on the floor of the digester tank is knows as sedimentation. Though some sources will claim that proper agitation will prevent sedimentation, this is not the true purpose of agitation. Agitation does help to keep the volume homogenous inside the digester vessel and prevents the formation of crust layers on the surface, both very important factors! But it is a fairly gentle process and internal velocities are not high enough to keep all material in suspension. To achieve this would require a large electrical draw, which would be very costly, and the bacteria community would be disrupted, causing biogas production to decrease.

If the feedstock contains small amounts of non-digestible sinking contaminants, the sedimentation rate will be slow enough not to affect biogas production over the lifetime of the facility. But if amounts are high, contaminants begin to take up more and more of the digestion volume over time. The more volume they take up, the less space remains for energy-containing matter and the less biogas is produced.

The Hard Truth

Eventually the plant operator must face the fact that his biogas plant is no longer operating at a functional level. Operations must be shut down. Loads of waste must be rejected or redirected to another facility. The interior of the digester tank has to be made accessible and the process of emptying the tank begins. On average, it will take an entire month for the cleanout process to be completed and costs can range from at least a few hundred thousand dollars into the millions of dollars, especially if you include lost revenue and the potential for lost feedstock contracts.

There Is Another Way

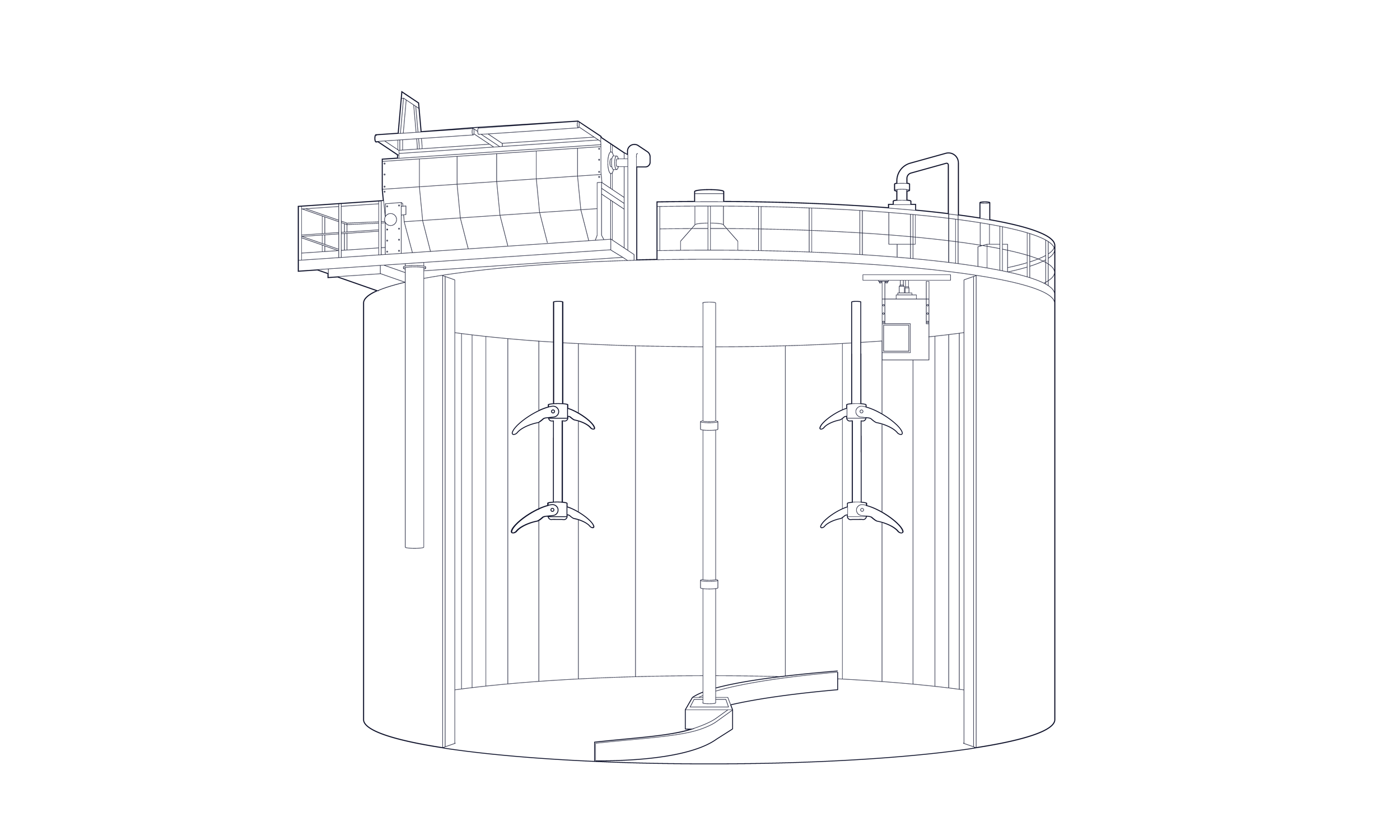

Except, there exists a different technology. One that allows operators to completely avoid the headache and profit draining experience that is the tank cleanout. It’s called The Fitec Self-Cleaning Digester. The Self-Cleaning Digester (SCD) makes use of the natural tendency for contaminants to sink and uses this to the operator’s advantage. A simple rotating arm or floor sweeper gently pushes accumulated sediment to a grit trap and pump chamber located just below the tank, keeping the tank free and clear of sedimentation and continuously operating at maximum energy production capacity.

Tried and Tested

The design of this system was motivated by engineers who were operating a biogas facility and were experiencing all the problems related to the digestion of contaminated materials. Multiple SCD plants are operating worldwide, some for over 20 years and counting. These systems are fed many tons of contaminants on a daily basis and have NEVER required cleanouts.

The Fitec Self-Cleaning Digester is easily operated and minimizes operating costs in multiple ways, making anaerobic digestion simpler and more profitable. You can find out more about how the SCD works by checking out our product page. There you will find technical details and links to videos showing the SCD in action. Alternatively, you can contact us today to plan a site visit and see the Fitec Difference for yourself.